Applications of Five-Axis Laser Machining Centers

- Aerospace: Used for machining high-precision, complex parts like turbine blades for jet engines.

- Automotive Manufacturing: Enables fast and accurate processing of complex car components, improving production efficiency and part quality.

- Mold Manufacturing: Produces high-precision mold parts to meet the demanding accuracy and efficiency requirements of the mold industry.

- Medical Devices: Processes precision medical components, ensuring safety and effectiveness.

- Electronics: Ideal for fine cutting and drilling multi-layer circuit boards, enhancing product reliability and performance.

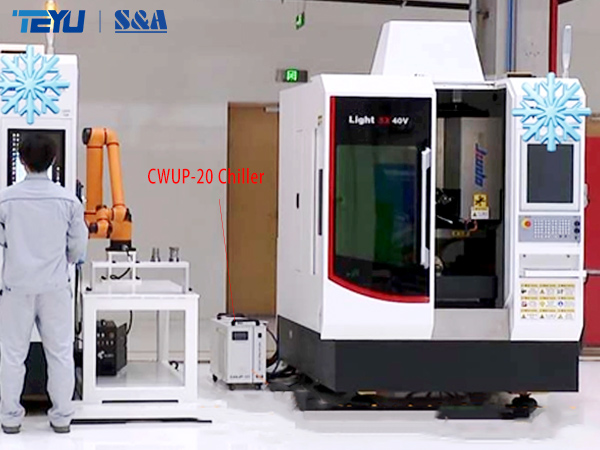

Efficient Cooling Systems for Five-Axis Laser Machining Centers

When operating at high loads for extended periods, key components such as the laser and cutting heads generate significant heat. To ensure consistent performance and high-quality machining, a reliable cooling system is crucial. The TEYU CWUP-20 ultrafast laser chiller is designed specifically for five-axis laser machining centers and offers the following benefits:

- High Cooling Capacity: With a cooling capacity of up to 1400W, CWUP-20 effectively lowers the temperature of the laser and cutting heads, preventing overheating.

- Precision Temperature Control: With a temperature control accuracy of ±0.1°C, it maintains stable water temperatures and minimizes fluctuations, ensuring optimal laser output and improved beam quality.

- Intelligent Features: The chiller offers both constant temperature and intelligent temperature adjustment modes. It supports the RS-485 Modbus communication protocol, allowing for remote monitoring and temperature adjustments.